|

| Researching fabrics available to the consumer |

Browsing through the features and classified section in magazines, such as Cloth, Making, Surface Design Journal, Handmade Living, Selvedge and Elle Decoration, I found the majority advertising here were selling printed cottons for crafts and dressmaking.

|

| Hannah's Room specialise in batik prints for quilting and patchwork |

Floral prints feature heavily in all these magazines and there looks to be a trend in both fashion and furnishings for textured animal prints, particularly fake fur and large romantic blooms (for SS 2013, dark backgrounds replace light). In homeware, nostalgic Cath Kidston and Amy Butler style florals and reproduction block prints are popular. Fair Isle designs, which featured on the catwalks AW 2011, are still around in furnishings, along with crochet, screen prints and patchwork.

|

| Florals Dominate |

There is ample choice of vintage fabric suppliers in the classifieds and on auction sites. Reclaimed kimono silks, retro Scandinavian folk style screen prints and 'atomic' barkcloth prints from the '40s to '60s are sought after. Ditsy floral prints from 1980's Laura Ashley and Liberty are also popular. This reflects the common theme of courses and workshops advertised in the magazines. 'Make Do and Mend', 'Vintage Dressing', Survive and Revive', 'Hand Alterations and Upcycling' are just a few of many similar. The Eurozone is still in recession and there is a growing movement of designers such as Junky Styling London who are working against fast fashion, sustainably, and with recycled materials.

|

| Vintage/reclaimed fabrics are popular for furnishings such as these kimono silk remnants and modern crazy patchwork in brights is still a furnishing trend |

Other suppliers specialise in fabric for artists and designers, such as Exotic Silks, who supply 1400 different types from Habotai for painting and linings to crepe de Chine for dressmaking and charmeuse for lingerie and drapey luxury items. Locally, I found Whaleys in Bradford who stock an enormous choice, available in any quantity from 1 metre. There are whole ranges of synthetic and natural fabrics prepared for dyeing and printing, coated fabrics for digital printing, dissolvables, discharge fabrics, devores, jutes, hessians, buckrams, linens, mixed fibres and more. There is even a department specialising in flameproof stage fabrics for theatre curtains and sets. Millinery net, organic cottons and many fabrics I'd never even heard of such as Pinukpop, hair canvas (interfacing for high quality tailoring) and even black delaine wool for nun's veiling are on the price list. (Interesting page on Nun's Veiling on Page 73 of Issue 49 Selvedge magazine.)

Fabworks Mill Shop in Dewsbury, is well used by schools as a resource for creative textiles, selling a wide variety of interesting scraps and remnants, along with fabrics for fashion, dance wear and furnishings. Textile artist Mister Finch, whose work was featured in the most recent Selvedge magazine (Issue 50) introduced me to Scrap in Leeds. This is a social enterprise that rescues waste fabric and materials destined for landfill and sells it on very cheaply to schools, community groups, students and individuals for art and play.

|

| Destined for landfill but now on sale at Scrap for creative re-use |

When I visited Scrap with the OCA students recently after a Yorkshire Group visit to the Nike Savvas exhibition, we were all fascinated. It's not somewhere you can go with a list of things to buy because you have no idea what you might find. It's an amazing place to pick up the unusual, be inspired and cheaply buy fabric and materials to experiment with - though you won't necessarily know what it is you have bought! I came out with a huge designer wallpaper sample book (for wrapping paper, book covers and collage), a stack of 6" squares made of something resembling Tyvek that I've been stitching into and apparently takes ink very well, a load of punched Jacquard loom weaving cards (thinking of weaving into them for the next assignment) and most usefully for this research point, a large number of samples of furnishing fabrics that included detailed specification, composition and fabric care advice.

|

| Yorkshire Textile Artist Mister Finch who created my moths buys materials from Scrap Stuff |

One large binder of samples was from Agua, whose background is supplying upholstery fabrics to the healthcare sector. They now describe themselves as 'a market leader in technical upholstery and curtain fabrics for all contract markets.' The fabrics have a luxury feel (many are convincing look-a-likes for leather, velvet and woven cotton) but each range has additional performance properties that makes them suitable for use in leisure, hospitality, cruise liners or healthcare. Desirable qualities for these settings might include anti-microbial, stain resistance, flame retardance, waterproofing, UV resistance, breathability, hard-wearing and wipeclean. This was the first time I've taken much notice of specifications and I was surprised by just how much information is contained. I was expecting composition and fabric care but not necessarily test results and standards for tear strength, tensile strength, pilling, urea resistance etc. Making up instructions include recommended number of stitches per 10cm and minimum seam bite on the fabric.

|

| Hardwearing technical upholstery fabrics like these might be used for fixed seating in leisure, hospitality or health centres |

I also acquired two small chained sets of upholstery fabric sample chips from Pallas Textiles. One Jacquard pattern is called Transom and is part of an earthy coloured collection called 'Plantation' that was inspired by aerial views of freshly ploughed fields. The other is a plaid weave called Kwaart, named after the transparent glaze used by Delft potters. It has irregular metallic threads running through representing the high gloss and depth of colour of the Dutch porcelain. Both patterns are 100% polyester but have been treated by a process called Crypton (see video), which makes the fabric a barrier impenetrable to spills, odours and bacteria. It's therefore suitable for settings such as hospitals or hotels where it could be used in headboards, panel or mattress fabrics.

|

| 'Crypton' treated upholstery fabrics are impenetrable to odours, spills and bacteria so are ideal for the healthcare sector |

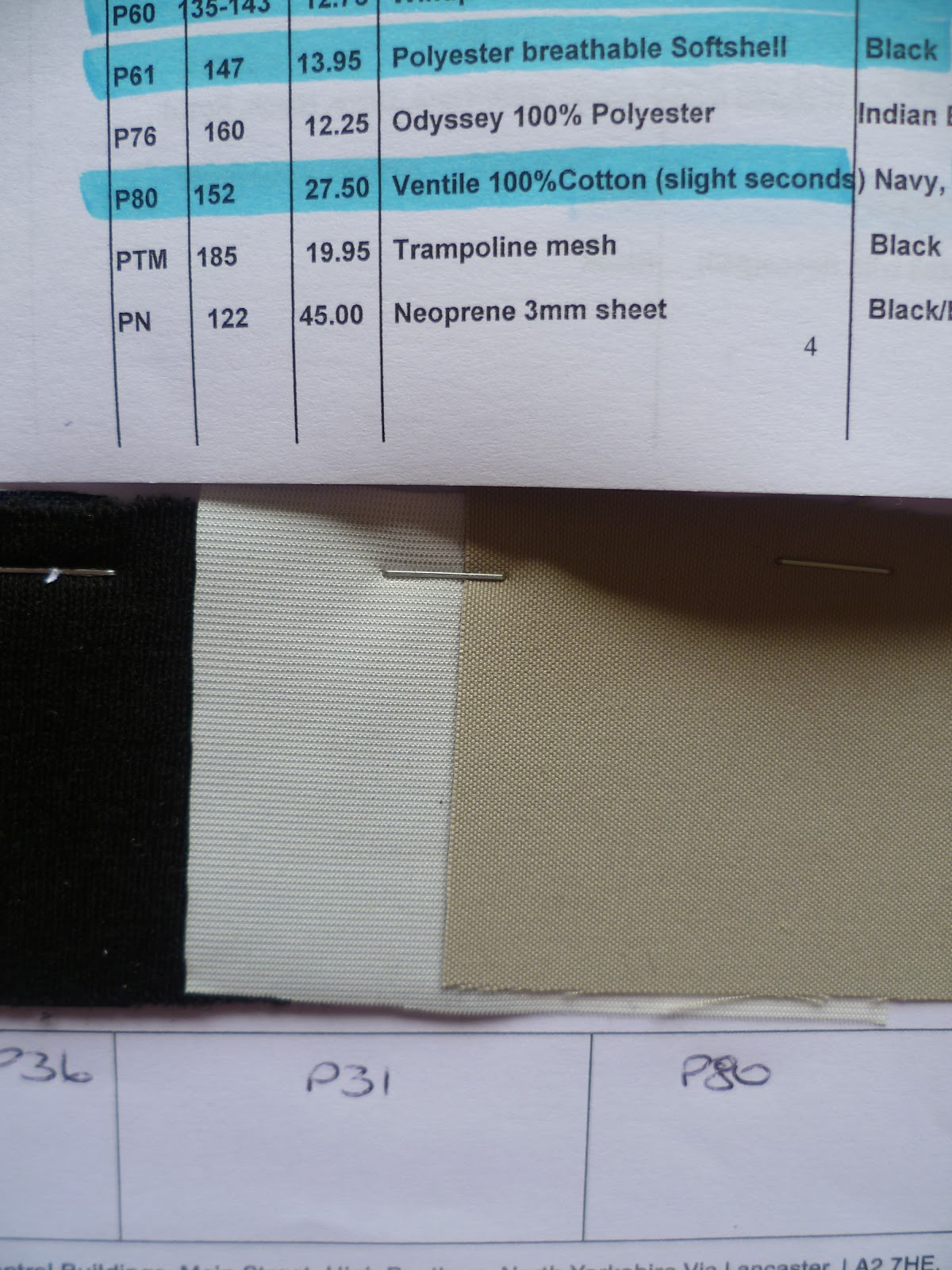

I became more interested in performance fabrics and began to have a look to see what was happening locally. Firstly I contacted Pennine Outdoor Ltd, founded in 1962 in Holmfirth and now in the Dales. They sent me a representative sample selection of their specialist outdoor fabrics. Products range from trampoline mesh, deckchair canvas and fabrics for covers, awning and tents to performance fabrics like neoprene and Gaberdine (which I now know was invented by Thomas Burberry!) and lambskin fleece for clothing and bags. They told me their customers include small businesses, retail shops, schools, hospitals, outdoor activity centres and private individuals interested in making their own gear. As many of their customers use domestic sewing machines, the range of fabrics reflects this need and they also provide accessories like zips and buckles along with patterns and sewing/making up advice.

|

| Outdoor performance fabrics |

I decided investigate one of the fabrics from the sample selection in more detail. I chose Ventile which was invented in the UK out of necessity just prior to WW2 when a flax shortage was predicted (flax was then used to make fire hoses and water buckets). I found it interesting that it had such impressive water resistant properties, comparable to modern processed synthetic fabrics, despite being made from 100% cotton. It is the combination of an extremely dense weave and the swelling properties of the specific long cotton fibres when they come into contact with water which prevents water passage. Ventile claims to have unsurpassed breathability and one of its important properties which I'd never have considered previously is its quietness. There is no rustle and it is comfortable, so is an ideal fabric for hunting, nature watchers, photographers and the military.

We are also asked to find out whether there are any fabrics or techniques peculiar to where we live. Yorkshire is famous of course for its production of fine worsted woollen cloth but I didn't know that just down the road, a successful project has recently taken place to ensure that highly counterfeited textiles like worsted can be made uncopyable. I read about the project which had taken place at Huddersfield Textile Centre of Excellence and was delighted when they responded to my enquiries with an invitation to visit.

Technical Manager Craig Lawrance and Training and Learning Team Manager Richard Axe explained a little of the history of the research and training centre. They were interested to hear about the OCA Textile course and explained that often Textile students finish their degree course not understanding enough about the structure of fabric and need further training on entering the workplace. They advised me about TIKP (Textile Innovation Knowledge Platform), a free online resource they launched in November for textile students and anyone in the industry, providing information such as markets, technology updates and a 'knowledge area', explaining the science behind textile materials. (I will be posting details on the student forum.)

Craig took me on a tour of the centre. It was interesting to see the testing lab where materials are tested for the specifications on my samples I've been writing about - pilling, tear strength, crease resistance etc. I was very excited to find out more about the three main development projects they have been involved in: SigNature DNA, the world's first 3D weaving machine and Multiple Laser Surface Enhancement (MLSE).

SigNature DNA

Although I knew Yorkshire worsted cloth is highly prized for its fine quality and is used in Savile Row suits, I had no idea it was enjoying unprecedented demand from the Far East and can fetch up to £5000/metre! Unsurprisingly then, high quality worsteds with selvedge are among the most counterfeited area in Europe and the US, along with 'noble fibres' like cashmere, interior textiles and branded apparel (Burberry being one of the most copied brands). Craig explained that textiles are an easy target. Branded labels are easy to remove and re-fix and it is virtually impossible to spot a 'good' fake without laboratory testing. Provenance is becoming increasingly important to customers in countries like Japan where there is great concern about content and origin. Facts surrounding counterfeiting and the losses it causes are shocking:

'Counterfeit goods entering the European market in the past year have increased by 900%' (source: BBC News, 8 August 2010)

'30% of pharmaceuticals in developing countries have been identified as fake' (source: World Health Organization)

'Counterfeit medication kills an estimated 100,000 people a year and costs the pharmaceutical industry an estimated US$600 billion in global trade' (source: FBI)

Craig explained at the start of the project, which was part-financed by the European Regional Development Fund to assist the local textile industry in protecting their reputation, they purchased vials of botanical DNA from Applied DNA Sciences (ADNAS) in New York. The original DNA, which is from an undisclosed natural plant source looks like a thick cloudy white liquid. It has been isolated, segmented and reshuffled to create a unique marker which cannot be copied. The challenge for the Textile Centre of Excellence has been to perfect cost effective methods of impregnating textiles invisibly, at any stage of the process, without changing the material's quality and properties whatsoever. Forensic authentication needs to be instantly possible, absolute and definite, and detectable in any section of a fabric or yarn. The DNA marker must be robust enough to survive multiple washes and the extreme conditions of any processing.

The DNA marker used now is a clear solution of mostly water and when applied, it's invisible. Although a single vial may costs hundreds, only a very low concentration is needed to be detectable. It's applied using a spray, or in textiles, usually with an ordinary lubricant solution by standard lick roller. The process can be made even more cost effective by considering where to apply the marker, for example in the stripe of a pin stripe fabric. Considering the price the worsted fabric can fetch, the cost of applying the DNA marker is now negligible.

3D Weaving

Next I saw the structure, around 5cm deep that the 3D machine had been weaving in a continuous I-shape from glass strands. Craig explained that 3D fabric is fully integrated and loose fibre ends are not all on the same plane. Therefore weak points, that always occur when pieces of 2D material are joined, are almost eliminated. In clothing there is potential for whole garments to be produced without the need for stitching together separate pieces, reducing labour costs. Aerospace and motor industries have been particularly excited by this project as there are possibilities for massive reduction in weight of parts, which then reduces fuel usage and costs. Delamination and impact damage is greatly reduced in a consolidated 3D structure so there is major potential for improving vehicle safety.

MLSE

Craig said that this project was probably the most exciting because of the potential for massively reducing the environmental impact of textile production. Multiple Laser Surface Enhancement uses laser and plasma technology with inert gases in a controlled vacuum environment to make changes to fabric properties. Each required performance characteristic e.g. waterproofing or stain resistance, is achieved by altering the 'recipe' of gases and intensity. Technically superior products can be produced using significantly less time, water, energy and chemicals than traditional processes. (I wanted to know whether DNA markers could be applied with MLSE but not at the moment because the DNA would cross contaminate). Craig showed me some ordinary cotton fabric that had been prepared for dyeing using MLSE. There was no difference to the look or feel of the fabric whatsoever. I can't remember the exact impressive statistics, but when the MLSE treated fabric goes to the client to be coloured, it will be far more responsive to the chemical dye so uses far less and the process is much quicker.

|

| Example of environmental benefits of using MLSE to treat textiles for fire retardance |

Thinking about the staggering potential of MLSE to change the future of textile processing is overwhelming. I suggested in 10 years time the industry will be unrecognisable, but Craig said no. Change has started and it will happen much sooner than that. I think, probably like many OCA students with a background in craft and making, I was turned off by the idea of technology. However, after this research, particularly my enlightening morning at the Textile Centre of Excellence, my opinions have completely changed. The future for the textile industry in Yorkshire looks like being as rich and interesting as its past.

(Speaking of the past, the final part of this research point was to visit a local historic house to find out more about the furnishings. I made my visit but am waiting to hear back from the curator as there was limited information available. I'll write about this visit another day.)

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteGreat research write-up on textiles — the variety of materials and their uses is fascinating. Just like fabrics react differently to moisture, building materials also need proper treatment. At Wet2Dry Solutions, our waterproofing service ensures homes stay protected from seepage, damp walls and structural damage. Enjoyed reading your assignment!

ReplyDeleteInteresting research point on textiles and material performance — great academic breakdown! At LeakFoe, many homeowners searching for waterproofing dealers near me reach out to us to find durable, high-performance solutions for protecting walls and surfaces. Enjoyed reading this!

ReplyDelete